ICBC: Innovative funding for green infrastructure

In its latest climate report, ICBC New Zealand, the New Zealand arm of the Industrial and Commercial Bank of China (ICBC), has reaffirmed its commitment to supporting New Zealand’s climate transition and is actively identifying climate-related risks and opportunities.

“We are in the process of dynamically integrating the green financing concept into our operation and development and striving to create greater value for our stakeholders,” says James Gill, director of corporate and institutional banking at ICBC New Zealand. “We will concentrate our efforts on improving governance, strategy, risk management, metrics, and targets, striving to make greater contributions for a good future.”

Gill says the bank recognises the need for innovative funding solutions to address the country’s infrastructure needs and support the development of green infrastructure.

Over its 11 years of operation in New Zealand, ICBC New Zealand has played a significant role in key infrastructure projects. These include the Transmission Gully motorway, developed through a public-private partnership (PPP), and the Ruakura Superhub – a 490ha development in Hamilton – residential development areas, industrial, retail and logistics, including a 30ha inland port. “Supporting these projects is our way of helping to move New Zealand forward,” says Gill.

“ICBC New Zealand is passionate about the opportunity in New Zealand to build productivity-boosting, climate-resilient infrastructure and improve outcomes for the country.”

ICBC helps the world to go greener

As the world’s largest bank by total assets, ICBC is a global leader in sustainable development, promoting green finance and supporting projects that contribute to a sustainable future.

The bank’s latest Corporate Social Responsibility Report, released earlier this year, highlights its commitment to green finance and pursuit of innovation-driven development and new sustainable development opportunities.

Some of the bank’s contributions to sustainable projects include:

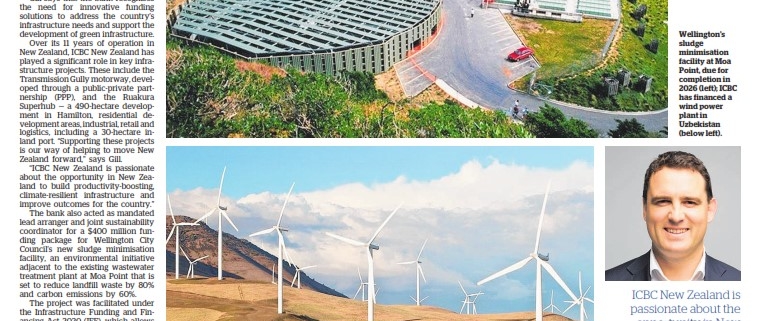

Uzbekistan wind power plant

The Dubai branch of ICBC acted as lead arranger, organising a US$900m international syndicated loan with international multilateral institutions to finance a major wind power project in Uzbekistan.

Upon completion, the project is expected to cut carbon emissions by 1.4 million tonnes annually.

By enhancing the power infrastructure in Central Asia, it will play a pivotal role in the region’s energy transition, contributing to global efforts towards sustainable economic and social development.

Green bus project in Hangzhou

The Hangzhou branch of ICBC has been instrumental in advancing Hangzhou’s new energy public transportation system.

The branch has provided over RMB4 billion in cumulative working capital loans and extended more than RMB1b in credits for projects including the acquisition of new energy buses and the construction of stations. As a result, all buses in Hangzhou’s downtown areas have been replaced by new energy buses, making low-carbon transportation a viable and popular choice for the city’s residents.

Marine carbon sink ecological products in Guangdong Province

Nan’ao County Island, located in South China, is home to Guangdong Province’s largest oyster cultivation base, with an annual output exceeding 30,000 tonnes.

Recognising the environmental benefits of oysters, which capture and store carbon dioxide as they grow, the Guangdong branch of ICBC introduced a “loan pledged with right to expected earnings of marine carbon sink” financing product.

This allows farmers to secure loans by pledging the expected earnings from the carbon sink value derived from their oysters, providing crucial financial support for sustainable aquaculture practices.

Green building project in Beijing

The Beijing branch of ICBC, acting as the lead bank, provided a syndicated loan of RMB270m to meet the funding needs of an enterprise for an intelligent green building project using prefabricated components.

After completion, it will be able to achieve an annual production capacity of one million square metres of prefabricated components, while solving problems such as noise, dust, material waste, and environmental pollution in the traditional construction industry and building material manufacture.